Car Settings (Part 1) - Tamiya RC Start Guide

1. Car settings (characterization)

There are various types of circuits, such as technical courses with many corners and high-speed courses with many straight lines. Setting up a car to suit such a circuit is the process. The best part of hobby RC is being able to enjoy various settings, from fine adjustments that can be made with standard parts to major changes in characteristics using optional parts.

Introduction How to proceed with the settings

There are many elements to the settings of an RC car, and each of them influences the other, so you will not get the results you want by just tinkering blindly. When working on the settings for the first time, it is a good idea to pay attention to the following points as you proceed.

Emphasis on drive wheel grip

In a rear-wheel drive vehicle, power is transmitted to the road surface from the rear wheels, and in a front-wheel drive vehicle, power is transmitted to the road surface from the front wheels, but if the drive wheels have poor grip, the power is wasted. Even in the case of four-wheel drive, the load shifts during acceleration, so the rear wheel grip carries a larger weight.

Rear wheel grip is the basis of stability

When a car turns, the rear wheels act as a fulcrum and the front wheels turn left and right, but if this fulcrum is unstable, the car will not be stable whether going straight or cornering. For this reason, in rear-wheel drive and four-wheel drive cars, the rear wheel grip should be given top priority, and then the grip of the front wheels should be increased. In front-wheel drive (FF) cars, the grip of the front wheels, which are the driving wheels, should be emphasized, but the grip of the rear wheels must be increased in balance.

Adjustments and changes can be made one at a time

If you change many items at once, even if the steering characteristics change, you won't know which adjustment or change is causing it. Try changing only the front tires, or stiffening only the front suspension, and adjust or change one part at a time to see the results. This will help you understand how each adjustment or change affects the settings, and make it easier to apply to other cars.

Left and right balance is also important

If the type of tires or stiffness of the suspension is different on the left and right, the car will have different characteristics in right and left corners. It is important to achieve the same balance on both sides, including wheel alignment and weight distribution. In addition, in oval races where the turning direction is extremely biased to one side, the balance may be disrupted by putting more weight on the inside of the corner of the chassis to increase cornering speed.

According to the climate and weather

When the temperature rises, the damper oil and grease become less sticky, and when the temperature drops, the viscosity increases and they feel harder. For this reason, it is necessary to adjust the oil and grease so that they have a higher viscosity in the summer and a lower viscosity in the winter. Furthermore, roads that are wet from rain become slippery, so adjustments to increase grip will be made, such as changing tires and strengthening the wing angle.

Setting sheet example (TA05 chassis)

For more detailed setting, setting sheets are available for each vehicle. These sheets are available in the download service section .

2. Gear ratio setting

The "gear ratio" setting determines how the power of the motor or engine is utilized. The gear ratio is the ratio of the number of teeth between the pinion gear attached to the shaft of the motor or engine and the spur gear that meshes with it, and in RC cars, it is generally adjusted by changing the pinion gear to one with a different number of teeth.

Top speed, acceleration and fuel economy are determined by the gear ratio

It is easy to understand the gear ratio by asking how many revolutions of the motor power are used to rotate the tire once. If the pinion gear attached to the motor has fewer teeth, the motor must rotate more to rotate the spur gear that meshes with the pinion gear once. In other words, more motor power (torque) is condensed to rotate the spur gear. This state is called a "large gear ratio" and the machine's acceleration power increases, but the maximum speed decreases. Conversely, if the pinion gear is replaced with one with more teeth, the spur gear can be rotated once with fewer motor revolutions. This is called a "small gear ratio" and the machine's maximum speed increases, but the motor power (torque) per revolution of the spur gear decreases, so acceleration slows. The gear ratio also changes when the number of teeth on the spur gear is changed, but in this case, it is easier to understand if you ask how many revolutions of the motor power are used.

- Does worn tires improve acceleration?

The diameter of the drive tire also affects the gear ratio. The smaller the tire diameter, the larger the gear ratio (emphasis on acceleration), and conversely, the larger the tire diameter, the smaller the gear ratio (emphasis on top speed). Therefore, there will be slight differences in acceleration performance and top speed between worn-out tires and new tires.

.jpg)

[Increase acceleration (increase gear ratio)] Pinion gear...increase the number of teeth (make it larger) Spur gear...decrease the number of teeth (make it smaller) Tire...increase the diameter

When changing motors, check the gear ratio!

As explained above, increasing the gear ratio increases acceleration, while decreasing it increases top speed. Motors and engines each have a gear ratio that efficiently extracts power, so it's important to adjust it within that range. Particular care is required when the gear ratio is small. If the gear ratio is too small for a low-power motor, the load on the motor increases, and there is a risk of it burning out. Conversely, if you use a high-performance motor with a high upper limit for torque and rotation speed with a gear ratio designed for a low-power motor, you may not be able to fully utilize its original power, so if you change the motor, you will need to reset the gear ratio accordingly.

Gear ratio setting is based on acceleration

The basic gear ratio setting is that on technical courses, a smaller pinion gear is used to prioritize acceleration (= gear ratio: large), and on high-speed courses, a larger pinion gear is used to prioritize top speed (= gear ratio: small).

When you begin the setup, start with an emphasis on acceleration (larger gear ratio), and gradually change to a smaller gear ratio (emphasis on top speed) while collecting data such as the lap time on the circuit and the number of laps you can run, to determine the best gear ratio.

Acceleration is key to improved fuel economy!

The larger the gear ratio (emphasis on acceleration), the longer the machine's running time tends to be, and the smaller the gear ratio (emphasis on top speed), the shorter the running time tends to be. In races that compete on the number of laps, such as 4-minute or 8-minute races, it is necessary to complete the specified time as well as the speed, so if you change the gear ratio, you need to be careful about the change in running time.

Small module gears are effective on clean circuits

The size of the gear teeth themselves is called the module. The 04 module, with its small teeth, has less drive loss, while the 06 module, with its large teeth, is characterized by its high strength. When changing the module of the pinion gear, the spur gear that meshes with the pinion gear must also be changed to a gear of the same module. Gears with smaller modules are superior in terms of driving performance, but the meshing adjustment range is more severe and there is a risk of the gear chipping due to pebbles getting stuck in the gear, so there are risks involved when using them on roads with poor conditions.

Left: SP.1423 FF-03 06 Spur Gear (68T) (ITEM 51423))

Right: OP.1227 FF-03 04 Spur Gear (102T) (ITEM 54227)

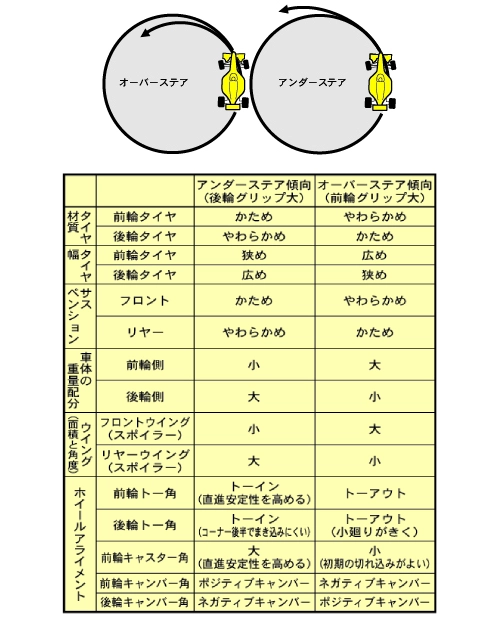

3.Steering characteristics

The terms "understeer" and "oversteer" are used to describe the steering characteristics of vehicles, not just RC cars. At slow speeds, a car turns exactly as the steering wheel is turned (this is called neutral steering). However

, as the speed increases, the car will tend to either not turn as much as the steering wheel is turned and will drift outward (understeer), or will turn inward more than the steering wheel is turned (oversteer).

Steering characteristic settings allow you to adjust the degree of understeer or oversteer to suit the driver's preferences and the characteristics of the circuit, making the car easier to control.

Understeer and oversteer are caused by differences in grip.

When a car goes around a corner, centrifugal force (lateral G) acts on the body, causing it to swerve out of the corner. The tires support the car so that it does not succumb to this force. When cornering, if the front wheels give in to centrifugal force and start to slide outward first, it is called "understeer," and if the rear wheels start to slide before the front wheels, it is called "oversteer." There are many main factors that affect understeer and oversteer, as shown in the diagram below.

4. Select your tires

Tires transmit the power of the motor or engine to the road surface, and also fight against centrifugal force when cornering. For this reason, tire selection is an important point in setting up the car. The tires used on RC cars can be broadly divided into two types: hollow rubber tires and sponge tires, and each type has different properties, such as the material they are made of and the size of their contact area (mainly width). Read another article about tire settings

Hollow rubber tires, slick type

They are often used as tires for RC touring cars, and the grip varies depending on the rubber material. Another appeal is the high realism that is reminiscent of the slick tires of real racing cars.

OP.224 1/10 4WD FF M2 Slick Tires (ITEM 53224)

Hollow rubber tire radial pattern

This tire has grooves like radial tires on real cars. The tire's starting movement is mild and easy to control. Its grip on smooth road surfaces is lower than that of slicks, but on roads with loose sand, it may grip better than slicks.

OP.227 1/10 4WD FF M2 Radial Tire (ITEM 53227)

Fiber Molded Tires

A stretch-resistant aramid fiber belt is molded on the inside of the tire tread surface. It is a mainstream item of high grip tires that not only prevents tire expansion during high speed rotation, but also increases tire rigidity to prevent tire deformation during cornering and provides stable grip. There are two types, Type A and Type B (B3), which have different grip characteristics depending on the road surface temperature. Type A does not change its grip performance much even when the road surface temperature changes, providing stable performance throughout the year and also featuring high wear resistance. Type B (B3) uses a special compound that provides high grip at high road surface temperatures.

OP.705 Fiber molded tires B3 (24mm width, 2 pieces)

Tire inner supports the tire from the inside

In hollow rubber tires, the sidewalls on both sides of the tire support the weight of the car. When cornering speed increases, the lateral force acting on the tire increases, causing the tire's sidewalls to bend outward, preventing the tread surface from properly touching the ground. Inner tires are used to prevent this.

Types of tire inners

Tire inners come in a variety of hardness levels, including belt-shaped inner sponges and donut-shaped molded inners that are molded to fit the inner shape of the tire. A softer inner tire will make the machine behave more gently, while a harder inner tire will improve response, but if it's too hard, the unevenness of the road surface will be transmitted directly to the tire, disrupting the machine's behavior. This depends on tire selection and suspension settings, so it's difficult to generalize, but basically, softer inner tires are better for low-grip surfaces, and harder inner tires are better for high-grip surfaces.

Inner sponge

This is the most basic tire inner. By putting a belt-shaped sponge inside the tire, the tread surface makes contact with the ground evenly, ensuring high grip and preventing uneven wear, and extending the life of the tire.

OP.156 Inner sponge, hard (4WD, FF) (ITEM 53156)

Sponge Tire

These tires have good grip on paved surfaces such as asphalt. The tread of the tire bites into the small unevenness of the road surface, providing high grip. However, they also have a weakness in that their grip drops drastically on wet roads.

OP.1168 F104 Sponge Tire B (4435 Rear)

Molded Inner

This is a tire inner made of polyurethane foam. It is harder than an inner sponge, and its main feature is that it does not shift or twist inside the tire. It fits snugly inside the tire, improving grip and preventing uneven tire wear.

OP.434 Molded inner Medium narrow soft (ITEM 53434)

Inner foam

It has a hardness between the inner sponge and the molded inner, and is thin at only 5mm. By creating a space between the wheel and the inner sponge, it has excellent shock absorption, improves traction, and enhances the initial steering response.

OP.295 Tire inner form (for narrow) (ITEM 53295)

Adhesion is key to getting 100% tire performance!

For hollow rubber tires, it is important to glue the tire and wheel. If the tire is not glued, the tire will distort significantly when cornering, and the wheel may rotate during sudden acceleration, resulting in loss of power. Instant adhesive is used to glue the tire, and we recommend instant tire adhesive (for rubber tires) which has low viscosity, penetrates into even the smallest gaps, and exerts strong adhesive power. In addition, the "Tire Gluing Adapter" is convenient because it allows for speedy gluing by simply setting the tire mounted on the wheel, creating a gap between the wheel and tire.

OP.339 Instant adhesive (for rubber tires) (ITEM 53339)

OP.338 Tire adhesive adapter (ITEM 53338)

A difference of 2mm can make the difference between victory and defeat! Tire width also affects vehicle behavior

The running characteristics of an RC car are affected not only by the material of the tire but also by the "width". On-road touring cars use narrow tires with a width of 26 mm and medium-narrow tires with a width of 24 mm, but in terms of running characteristics, medium-narrow tires are quicker because they are narrower and have a smaller contact area. In addition, both tires are different in diameter as well as width, with narrow tires being slightly larger. Therefore, narrow tires tend to have a higher top speed for machines under the same conditions (see the gear ratio section for details). In races where both types of tires can be used, one strategy is to use different tires depending on whether you want to prioritize responsiveness in cornering or top speed.

*The tires and wheel inners for medium-narrow tires and the tires, wheels, and inners for narrow tires are different sizes, so they cannot be combined.

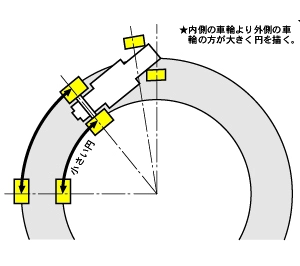

5. Differential

When a car goes around a corner, the outside wheels draw a larger circle than the inside wheels, so if the outside wheels don't rotate that much more, the car won't be able to corner smoothly. A differential is what makes each wheel rotate at a different speed depending on the radius of the circle drawn by the inside and outside wheels while cornering. Without a differential, the tires would be forced to slip when turning, making it difficult to turn and reducing grip.

Gear differential - Stable operation only possible with a mechanical system

The standard differential commonly used in real cars and RC cars is the gear differential. When the left and right wheels are firmly on the ground while driving straight, the entire differential rotates to transmit power to both wheels, and when cornering, the bevel gear rotates to adjust the difference in rotation speed between the two wheels. However, with a gear differential, if one wheel lifts off the road, power is only transmitted to the lifted wheel, causing it to spin freely, and power cannot be transmitted to the wheels that are on the ground (they do not rotate), resulting in a loss of driving force for the car. However, this characteristic can be mitigated to some extent by applying a high-viscosity grease such as anti-wear grease to the bevel gear to regulate the movement of the gears.

OP.439 Anti-wear grease (ITEM 53439)

Ball differential - Differential effectiveness can be freely adjusted -

A differential unique to RC cars is the ball differential, which consists of two steel balls sandwiched between two differential plates. The balls have the same effect as the small bevel gears in a gear differential, and the balls rotate during cornering to adjust the rotation speed of the left and right wheels. Even if one wheel lifts off the road, the friction of the balls transmits a certain amount of power to the other wheel, so there is no loss of driving force like with a gear differential. By adjusting the pressure of the differential plates that sandwich the balls with springs and screws, the effectiveness of the differential can be adjusted over a wide range. If the pressure of the differential plates is not strong enough, the differential itself will spin freely and will no longer transmit power, so regular adjustment is essential.

One-Way Unit

When cornering, the rotation speed of the tires differs not only between the inner and outer wheels, but also between the front and rear wheels, with the rear wheels drawing a smaller circle than the front wheels. The difference is not as large as the difference between the inner and outer wheels, but the front wheels rotate more than the rear wheels. That is why the "one-way unit" is available as an option for four-wheel drive machines. There are two types of one-way units: one that is inserted into the front wheel gearbox (front one-way) and one that is located between the front and rear wheels (center one-way). When this unit is installed, the front wheels can rotate faster than the shaft or belt, and the cornering characteristics are better for entering corners and more stable when exiting. However, care should be taken as it may be difficult to control on roads with poor grip.

6. Front-rear weight distribution

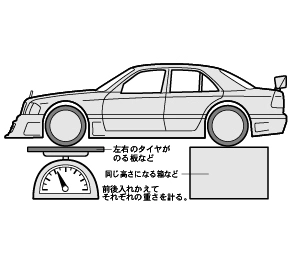

The more weight a tire bears, the stronger it is pressed against the road surface, and the greater its grip. This can also be used to adjust steering characteristics by changing whether more weight is placed on the front or rear wheels. In kit-type RC cars, the weight distribution is often about 35-45% at the front and 65-55% at the rear, assuming the vehicle's weight is 100. Placing heavy items such as the running battery closer to the front will distribute more weight to the front wheels, improving front wheel grip. Similarly, placing it closer to the rear will improve rear wheel grip. This weight distribution can be roughly determined using the method shown in the figure.

7. Wings, spoilers

Wing and spoiler settings are important in full-scale racing cars, but these aerodynamic parts also have a great effect on RC cars. The wings of full-scale F1 cars and other cars have a cross-section that is the opposite of that of an airplane wing, thin at the front and thick at the rear, which generates the force (lift) that makes an airplane fly in the opposite direction, and uses this force to press the car body against the road surface (downforce). However, RC car wing parts are often simple single pieces of wood, and can be said to function as "spoilers" that use wind pressure as downforce rather than lift.

Read another article about bodies and wings

1/10 ARTA Garaiya rear wing

The larger the area and angle, the greater the effect, but it also creates resistance.

The larger the wing area and the more angled it is, the greater the effect will be, and a front wing can increase grip on the front wheels, and a rear wing can increase grip on the rear wheels, but if the angle is too great, resistance will increase and speed will not increase. The more forward the wing is, and the more rearward the rear wheel is, the greater the effect will be, but there are restrictions on the size of the car when racing, and above all, installation that impairs the realism should be considered.

OP.604 Racing wing set (ITEM 53604)

The faster you go, the more effective the aerodynamic parts are.

The effect of aerodynamic parts such as wings and spoilers increases the faster the car goes. For example, if you attach a large wing to a car that tends to oversteer, the effect of the wing will be stronger at high speeds, reducing the oversteer, and the effect of the wing will be weaker at low speeds, returning the car to a tendency toward oversteer. In this way, you can change the steering tendency for each speed range.

However, if the body or stays are loose or easily bend, the powerful downforce generated at high speeds will not be transmitted to the wheels, so make sure to securely fasten the wing and body mounts.